Composite chainplates

From very early on, I’ve been planning to use synthetic standing rigging instead of wires. It doesn’t corrode, it’s lighter, and I can install it myself – no wire terminals that require a machine to make, just lashings and splices everywhere. What I didn’t like was that I would get rid of the metal in the shrouds, but still have to attach them to metal chainplates. Until I found out about composite chainplates.

Conventional metal chainplate.

Composite chainplates are not really plates. Instead, you take a tube (stainless steel, titanium), wrap a lot of (carbon, glass) fibers around it, bring the fibers onto a surface like the hull or a bulkhead, fan them out and glue them on with epoxy. This is what it looks like in practice:

Photo from dixdesign.com.

As you can see, the composite “plate” is bonded to a much larger surface area than the bolted-on piece of metal, which should result in a stronger bond.

An additional problem with metal (apart from corrosion) is, that it flexes and expands/shrinks (with temperature) differently from fiberglass, meaning the chainplates sooner or later start to leak. No problem with composite, where hull and chainplate become one piece.

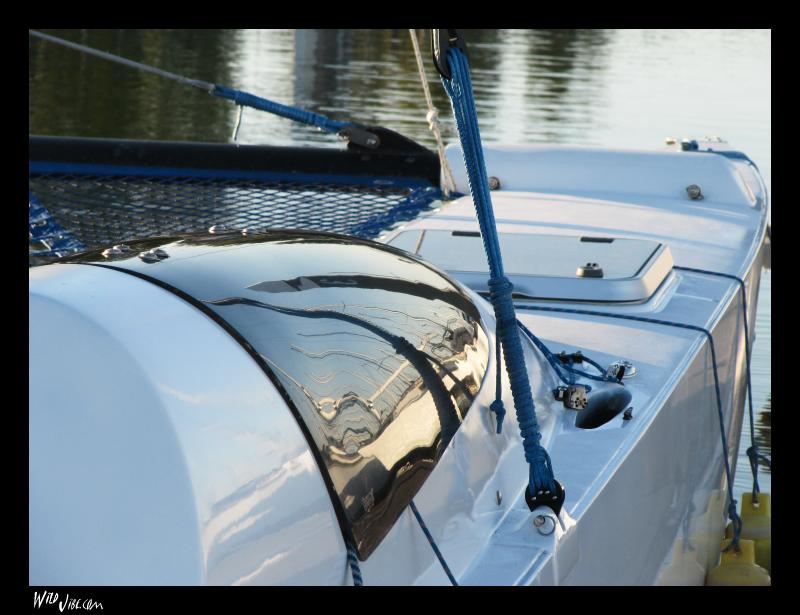

Also, they look way cooler (via).

As it so happens, Dudley Dix (who designed my boat), has already used composite chainplates, but for a different design. Now I just have to convince him to adapt the specs to my Mini.

Comments